- Grbl controller manual install#

- Grbl controller manual serial#

- Grbl controller manual manual#

- Grbl controller manual full#

The $x=val command saves or alters a Grbl setting, which can be done manually by sending this command when connected to Grbl through a serial terminal program, but most Grbl GUIs will do this for you as a user-friendly feature. However, most good GUIs will help out by attaching descriptions for you, so you know what you are looking at. This was done to free up precious flash memory to add the new features available in v1.1. In prior versions of Grbl, each setting had a description next to it in () parentheses, but Grbl v1.1+ no longer includes them unfortunately. The x of $x=val indicates a particular setting, while val is the setting value.

All of these settings are persistent and kept in EEPROM, so if you power down, these will be loaded back up the next time you power up your Arduino. Grbl should respond with a list of the current system settings, as shown in the example below. To view the settings, type $$ and press enter after connecting to Grbl.

These either immediately change Grbl's running behavior or immediately print a report of the important realtime data like current position (aka DRO).

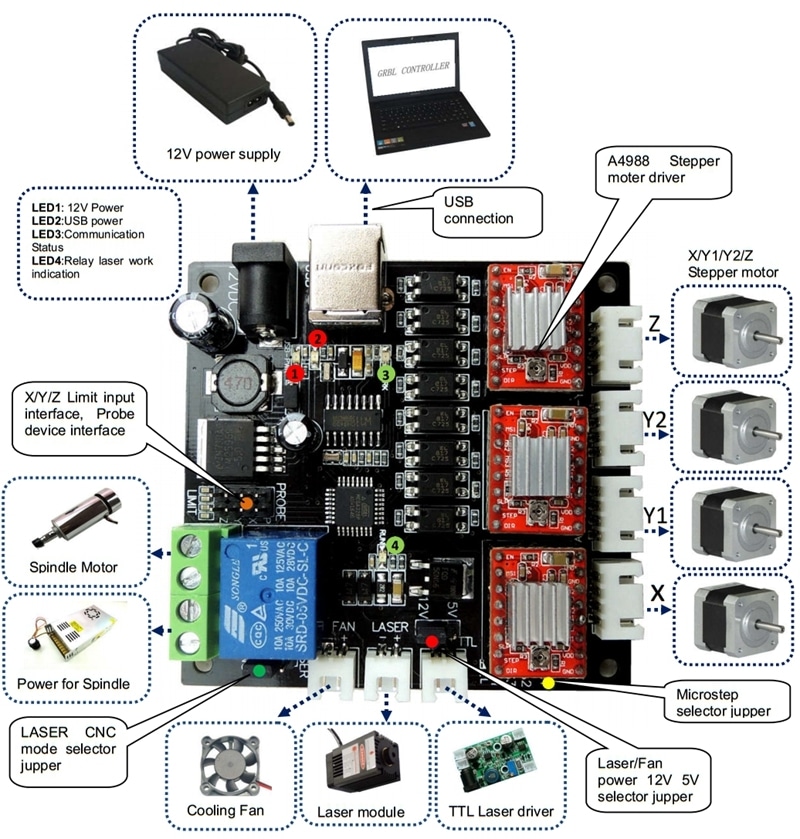

The last four non-'$' commands are realtime control commands that can be sent at anytime, no matter what Grbl is doing. The ‘$’-commands are Grbl system commands used to tweak the settings, view or change Grbl's states and running modes, and start a homing cycle. You should not see any local echo of the $ and enter. Type $ and press enter to have Grbl print a help message. Once connected you should get the Grbl-prompt, which looks like this: Grbl 1.1f Set the baud rate to 115200 as 8-N-1 (8-bits, no parity, and 1-stop bit.) Quick Guide to Setting Up Your Machine for the First Timeįirst, connect to Grbl using the serial terminal of your choice.According to the high frequency heating, thermal expansion and contraction principle, to expand the hole, then insert the spindle and lock it, and then fix the shaft collet after cooling completely. Installation: The aperture is smaller than the actual 0.02mm.

Grbl controller manual install#

Generally, it’s a little difficult to install ER11 holder. We suggest cnc-based buyers to buy, this machine is not industrial grade level.

Grbl controller manual full#

The machine for a full set of spare parts, shall be installed by the buyers.

Grbl controller manual manual#

Support system: windows xp, win7, win8, win 10, linuxĭrill bits: Diameter: 3.175mm tip: 0.1mm length: 30mmġ x Disk(include the English manual and software) Step motor: Fuselage length 34MM, Current 1.33A, 12v. Mesa: aluminum plate(100x180mm) + plastic

0 kommentar(er)

0 kommentar(er)